No growth? squeeze the lemon!

It seems that everything comes to a hold due to the panic all around. The reality of here and now is a drop in volume to levels of 2006/2007. Most terminals will end 2008 still at par with 2007 as the first 9 months showed steady growth. However, the dramatic drop since October makes the growth undone. So reality has changed, and is likely to be like this for at least for the coming year, or 2. What shall we do?

Doing more with less

In the training session we give to various customers, we preach the mantra “doing more with less” or “squeezing the lemon”. Not only in times where cost cutting is key, but as common practice. However, many terminals have been so overwhelmed with volume increases over the last decade, that the focus has been on accommodating growth rather than streamlining operations. As more volume typically outweighs (financially) the benefit of cost cutting, i.e. more volume contributes more to the net profit than focussing on efficiency - this because of the significant margins in terminal operations – we have become sloppy, in the sense that there is waste, much waste in terminal’s operations. Now it becomes of utmost importance to keep the result above water level, we have to see where we can save, and improve the balance between performance (throughput, berth productivity, quay crane productivity) and operational cost. Also, lower volumes mean that the yard is less occupied, providing room for an increase in equipment productivity: less shuffling, leads to a higher productivity of equipment, at least if we also adjust deployment to proper levels. Which can result in conflicts with the labour unions, not willing to reduce resource utilisation.

So “doing more with less” requires different thinking than just expansion, trying (desperately in some cases) to accommodate the volume.

In the past times we have been working on several of these projects to make the terminals produce a better balance between their customer service and their operational expenditures, analysing resource deployment, yard strategies, layouts, operational procedures, etc. These projects typically contain quite some (time consuming) change management, as change is necessary to make the improvements. However, the results so far are very promising. Increased capacity on same footprint, lower driving distances, less equipment waste, less unproductive moves, and so on. Not uncommon are cost reductions (without impact on service levels) of 10 – 20% of OPEX.....So we are talking big money, and enough to bring operations back into the black numbers.

Productive and systematic

Well, how to tackle this lemon squeeze in a productive, systematic way? If you go into the various departments of a container terminal (e.g. operations, maintenance & engineering, marketing, IT, human resource management, terminal management), you will typically find very different opinions about what is wrong, and what can be improved. Here we have to deal with perceptions and coloured opinions, which we should transform in root causes of terminal inefficiency. Only then, when we have done a proper diagnosis, we can and should make the step to solutions. Solutions that actually solve the true problems, and not counteract symptoms of the problem. Then we need to find out which solutions are actually worthwhile to implement. By means of categorising the solutions, after proper evaluation of course, we come to a priority list; one that can be executed step by step, starting with the “cash cows” (see fig), followed by the “stars”, and possibly also by the “question marks”. The “dogs” we should not burn our fingers on.

TBA’s improvement matrix (free after the BCG matrix).

When we have determined which solutions are worthwhile to implement, we should act. Carefully, with a dedicated team, and whilst measuring before and aft. This to ensure that we are accomplishing our goals, and can steer when necessary. We have to keep in mind that change is not easy, but if we do not persist, we have a problem long term. Therefore, support from the terminal management is essential. Sometimes, unpleasant measures have to be taken, and there are always reasons why not to do it. An external group that performs the analysis has the advantages of fresh eyes, no bindings with the staff and the experience of (preferably many) other terminals.

Reliable numbers

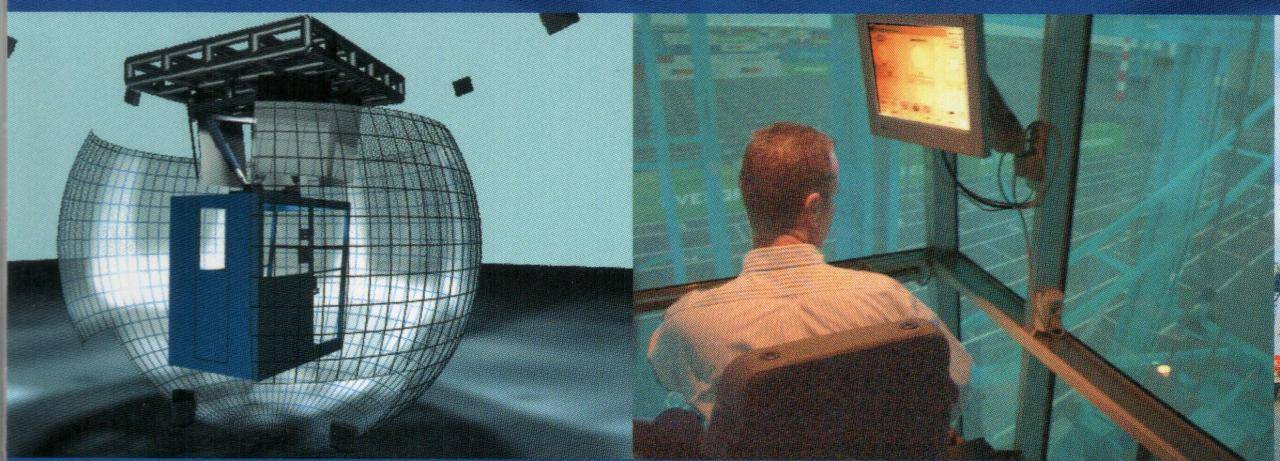

The way we tackle the improvement process, trying to convince the management and the other departments, is using reliable numbers. The highly quantitative approach (using detailed simulation, replaying 4 – 6 weeks of real operation, which an accuracy of beyond 95%), leads to the ability to objectively assess the contribution of an improvement measure. Instead of perceptions, opinions, strong opinions, beliefs, gut feel, pessimism (or optimism for that matter), we have comparisons of the contribution to performance and cost of every single improvement measure, or combinations of them. Although this approach can be time-consuming (typically we spend 6 – 12 months on a process like this), the results are solid, and there is afterwards no time lost on working on measures that have no contribution. Besides, the things that are clear from the beginning (the so-called low hanging fruit), we can start solving immediately, but in most self-respecting terminals, this waste is merely gone, or still there because of other – more difficultly solvable reasons.

What’s the premise of all this? Well, I’d say on average:

- More volume (10 – 15%) without additional investments, even when the yard is considered “full”.

- Less equipment deployment (10 – 25%) without lesser “performance” or service levels.

- Higher performance or service levels (5 – 10%) without additional equipment.

So there is enough to do, now we are not so busy. We should revisit our own processes, and see whether we can be better prepared for the future. And the future will bring – no doubt from my side – more volume. The million dollar question is of course “when”. Well, let’s tackle what we can tackle and be prepared, the growth will come by itself.

Squeezing the lemon? Yes, but please analyse, quantify and then decide!

This article has been published in Port Technology Magazine in August 2009.

Share this

You May Also Like

These Related Stories

Human Machine Interfaces - the key to productivity?

The journey of CONTROLS: DPW Antwerp