Most container terminals world-wide are equipped with RTGs and terminal trucks. Imagine you are responsible for one of these terminals these days. Volumes are growing as a result of global trade growth, productivity demands are also going through the roof due to increased vessel and call sizes, and at the same time, there is the pressure to electrify to reduce the carbon footprint of the typically diesel-powered equipment fleet.

Sounds familiar? What if there is a way to significantly reduce the investment ahead? A way that has proven itself in one ultra-large container terminal, with a mixed (diesel, hybrid and fully electric) fleet of 100+ RTG’s?

An example

Let’s assume you are currently handling some 1.5M TEUs annually, mostly gateway volume. Your terminal is equipped with 10 STS and approximately 30 RTGs. Now you are planning the CAPEX to support the expected growth in volume to 2.0M TEU.You have factored that an additional 10 machines are required, which will heb require a heavy CAPEX of some 15 Million USD. What if there is an alternative, which would enable you just to purchase 6 RTGs, instead of 10? At the same time, reducing OPEX by 700K –1.2M USD / year?

ROI of less than 6 months

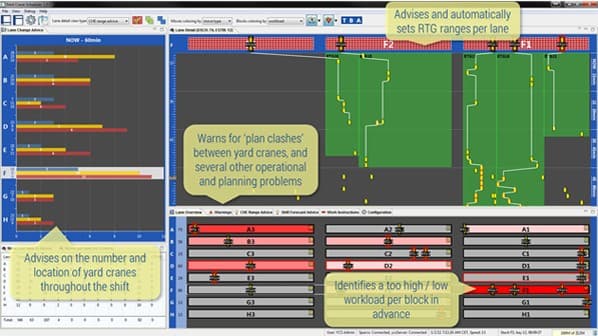

This alternative is there. Readily available for any terminal running the NAVIS N4 TOS. It is called Yard Crane Scheduler and provides fully automated RTG scheduling and dispatching. It has proven to increase RTG productivity by a mere 10%, still with more potential. The ROI of YCS is less than 6 months for any terminal over 1M TEU. Saving OPEX, reducing the carbon footprint, and creating a more predictable, consistent operation. Improved waterside productivity, better truck turn times towards the gate.

No change to TOS needed

YCS can be implemented without any changes to the TOS, provides a high degree of automation and enables the terminal management to move towards pro-active rather than re-active operational control.

For more information about tuned system performance please visit this page