‘What I hear, I forget.

What I see, I remember.

What I do, I understand.’ (Confucius)

Confucius already knew that learning by doing is the only way of effective learning; and learning is needed in our industry. As productivity demand is ever-increasing, and complexity of systems and operations – not in the least driven by automation, and the introduction of even more systems – is increasing, people need to be trained to be effective at what they do.

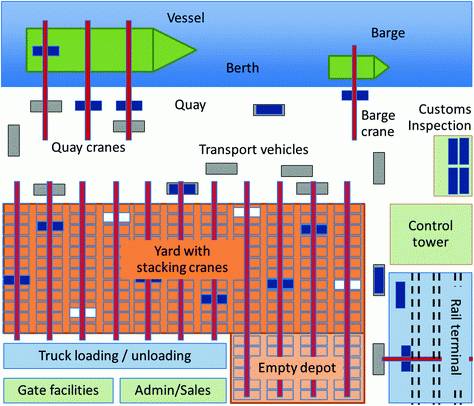

The article talks about people controlling operations through the various systems present, i.e. planners, supervisors, dispatchers. How can they become better trained applying Confucian style learning?

Room for improvement

The need for training starts with the efficiency gap currently existing. What can we gain if our operational control staff – this term I’ll use from now to address the staff planning the work (yard, vessel, rail), supervising the execution, solving incidents, and allocating and directing equipment in real-time – would be better trained? When we started our training programs, we never envisioned that the gap could be as large as we know now. Having put hundreds of operational control staff through our training programs, we found that by improving their capabilities and applying best practices, average productivity levels could be increased as much as 30%.

Figure 1: Results of improved planning skills of trainees. The result is the average of approximately 100 trainees, all doing the same iterative training program. Inbetween the planning exercises, short class-room training sessions were given, and feedback was given to their previous plans. On average, the performance increased by 35% from the initial results to the final results.

We also found that the difference between the worst performer and the best performer is typically in the range of 50-60% in achieved productivity levels. Finally, we found that with the use of more automated tools – in many cases already licensed but poorly used – the consistency and performance of operations could be substantially increased as well.

Figure 2: This graph illustrates an example of a training of 30 vessel planners (P1 – P30), and there individual result, planning two vessels with each 3 QC’s. The best planners achieved average berth (vessel) productivities of 60 – 70 containers per hour, whilst the worst planners only achieved 40 – 50 containers per hour. Under exactly the same circumstances! Same yard, same equipment, same drivers. Just their plan to make the difference. This wide range of results, we typically find with our near-to-live training sessions.

The most common training methods today in the maritime industry are on-the-job training and class room training, mainly through standard deck of PowerPoint slides (boring!). The effectiveness of this training method has proven to be less than 10% (in the sense of what people remember from the material presented).

Learning by doing

Therefore, time for learning by doing. In various forms, depending on the trainees, and the objectives of the training, we have developed training programs – ranging from 3 days to full weeks – in which trainees are confronted with plan preparation, planning, and work execution type jobs, that are similar to the ones they have to perform in live operations. Tasks range from setting up the yard, planning discharge containers, decking export receivals coming in through the gate, determining how much equipment shall be deployed in the upcoming shift, allocating equipment in real-time to yard locations, planning the crane split, the quay crane work queues, et cetera. In principle, the entire coverage of operational control staff.

Feedback after every iteration in typical KPI’s

After each training cycle (typically we follow multiple cycles to enhance the learning experience), a feedback session follows. The feedback is based on the actual KPI’s they achieved (e.g. vessel productivity, quay crane productivity, yard crane productivity, operational costs, truck turn time), as well as on the assessment of what they did (assessed by one of our trainers). In order to create the KPI’s, our terminal emulation tool CONTROLS is run (overnight) to get the results for each trainee in a comparable way.

Figure 3: The cycle followed in the training. In an iterative way, trainees find out how to apply best practices in their plans, and receive in each iteration feedback about their solutions.

Competition element as motivator and fun factor

The last but essential element in the training is competition. Either individually, or in groups the plans are made. After every submitted or executed plan, the KPI’s are compared, and the trainees or teams of trainees are extremely motivated to be the best in class. As there is a level playing field, each trainee or team of trainees has equals chances to prepare the terminal in the most cost-efficient or productive way, without excuses. Every team works under exactly the same circumstances, with the same resources.

From gamification to certification

Today, training in the form of games is a well-received, and highly appreciated method. However, we expect that this can and will be brought to the next level. Operational control staff can be tested before being deployed in live operations. With well-developed and configured scenarios, they can be trained and then tested in their capabilities to deal with uncertainty, dynamic events, peak loads, and all kind of other circumstances that make work in a terminal so challenging. This could lead to certified vessel planners, yard planners, and supervisors, and as such bring accreditation to the profession, as well as higher standards, and most likely better performing container terminals.

This article has been published in Port Technology Magazine in November 2014.

Share this

You May Also Like

These Related Stories

The Future: Serious Gaming in Automated Terminals

TBA Training Portal used at Lamar University increases study performance levels in terminal logistics