Warehouse Automation Systems

Turnkey automation systems and equipment control solutions for warehouse environments. Real-time automation control tools that optimise safety, productivity and longevity.

Allowing you to

increase efficiency

Proven automation systems that enhances business continuity to keep your operations running at maximum efficiency - 24/7 support offers complete peace of mind.

Giving you tools to improve performance

Delivering process, safety and performance improvement in complex semi and fully automated environments.

Improving your operational control

Fixed, programmable and flexible automation solutions, that reduce risk, cut OPEX and boost productivity.

Speak to an expert

Get in touch to arrange to speak with one of our warehouse automation experts, who will be able to answer your questions and give you all the information you need.

Why choose TBA automation system solutions?

Intelligent Solutions

Maximise CAPEX and minimise OPEX with intelligent automation solutions & 24/7 support service.

Tried & Tested

Proven solution in semi-automated & fully automated warehouse environments.

Wide Integration

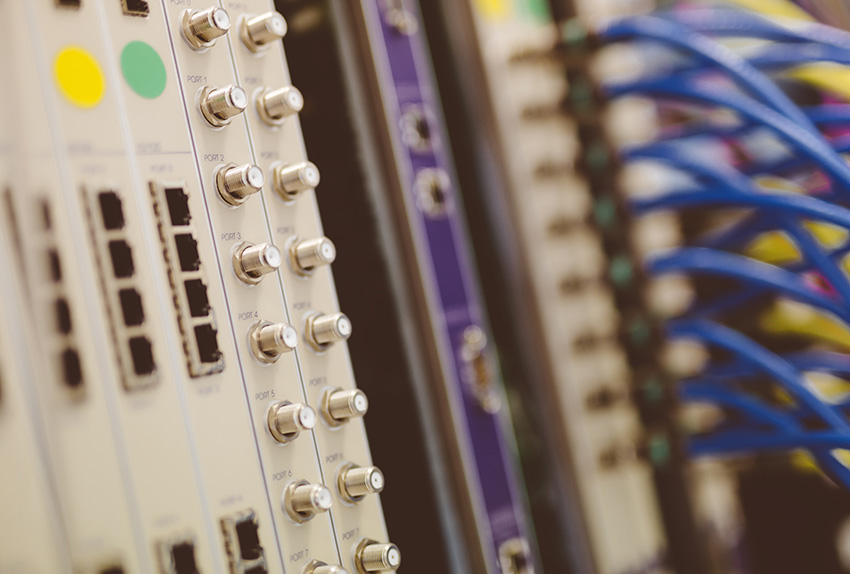

Integrate with automated material handling systems and hardware from leading manufacturers.

Warehouse automation solutions for demanding environments

A range of rugged equipment control software solutions that ensure optimised automation applications for performance improvement and longevity. We also deploy pre-developed structure blocks for PLC and SCADA to reduce surplus programming, cut commissioning time and reduce errors.

Autostore WCS

Automation Software

Wide Compatibility

Certification

Fault Finding

Auto-Recovery

Discover how TBA automation can help with your...

Narrow Aisle Cranes

Conveyor Systems

Automation/WMS Gateways

Industrial Networks

EN-ISO 13849 Safety Systems

Don't just take our word for it

Read what our customers say about us.